Sure! I used (in order from exhaust flange):

Existing exhaust outlet flange- was previously bored out to fit 2.25" tube

2x 45 degree 2.25" (57mm) bends (for the downpipe- 2.25" clears the retaining springs, two bends moves it away from the bellhousing)

1x 2.25" to 2.5" (63mm) flare (just before the hotdog style muffler).

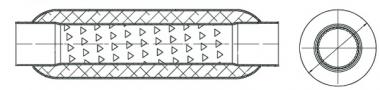

500mm long 63mm inlet/outlet louvered centre tube hotdog muffler (the louvres make it quieter, but I suspect they've given it a slight whistle. I'd go for a perforated centre tube if I was doing it again. Open side of louvres face the engine).

- faa14f3e3c4270c8937f3073fdd3bb411f0228b2.jpg (8.85 KiB) Viewed 6472 times

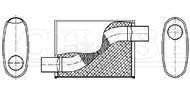

255mm x 105mm oval 63mm in/outlet offset/offset straight through muffler (I didn't want to risk the flow loss of a chambered muffler)

- RD41463.jpg (4.4 KiB) Viewed 6472 times

Half a 63mm donut for the sharp turn.

A short length of 63mm pipe- my bends had fairly long tails, so I just used a piece off one of them.

1x 180 degree 63mm bend (conveniently wide enough to go around the spring hanger)

1x 90 degree 63mm bend

Recycled exhaust tip.

I've since had to add a bracket to stop the exhaust tip vibrating at about 1500rpm:

- bracket2.jpg (48.28 KiB) Viewed 6472 times

- Bracket.JPG (268.85 KiB) Viewed 6472 times

You can probably see in the above photos that I had to double up the right side exhaust hanger as it was taking most of the weight. Doubling it up also stops the exhaust from moving sideways too much and hitting the spring mount.

Nothing says "poor workmanship" more than wrinkles in the duct tape.