Page 1 of 1

1,5" lift block

Posted: Thu Aug 12, 2010 9:36 am

by fexlboi

I'm trying to find a 70mm wide and 1 - 1,5" high block to lift the rear axle. Called NSOR and a couple spring shops, but no one has this size. Any idea where I can get one?

Update: It turned I can use a different size of block too. Not sure way Canada Spring declined to install anything else than a 70mm wide block.

The block I have right now is 2.5" wide and 5.5" long. The front is 2 13/16 and the back 3 3/16 high.

Re: 70mm x 1,5" lift block

Posted: Thu Aug 12, 2010 10:24 am

by strada-caster

2" block and put it on a milling machine...wouldn't cost more than a few bucks from any machine shop to accomplish. might even do it for a few beers if you find the small little unknown shops.

Re: 70mm x 1,5" lift block

Posted: Thu Aug 12, 2010 1:16 pm

by fexlboi

I'm not too worried about the height. The 70mm width is tricky to find. I might can use my old 2.5" blocks and take them to a milling shop. Any recommendations in the lower mainland area?

Re: 70mm x 1,5" lift block

Posted: Thu Aug 12, 2010 11:25 pm

by jessef

Or you can buy the wider than 70mm angled shim (for the diff angle in relation to the output shape angle on the tcase) and just cut off the excess to leave 70mm width.

Re: 70mm x 1,5" lift block

Posted: Thu Aug 12, 2010 11:45 pm

by fexlboi

jfarsang wrote:Or you can buy the wider than 70mm angled shim (for the diff angle in relation to the output shape angle on the tcase) and just cut off the excess to leave 70mm width.

I don't actually know why it have to be exactly 70mm anyway. To me it looks a 3" would fit as well. The spring shop wants me to get exactly an 70mm block.

This block doesn't seem to be angled. At least what I can tell

Re: 70mm x 1,5" lift block

Posted: Fri Aug 13, 2010 9:55 am

by Lars

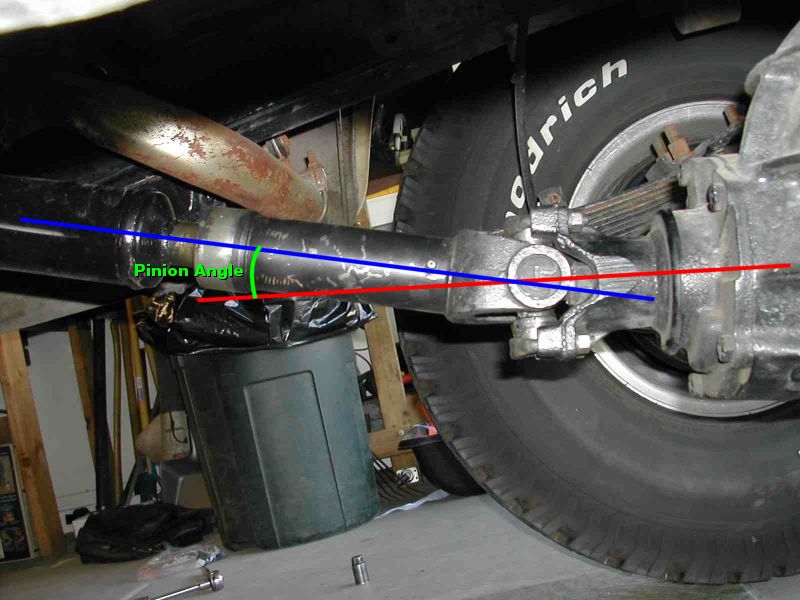

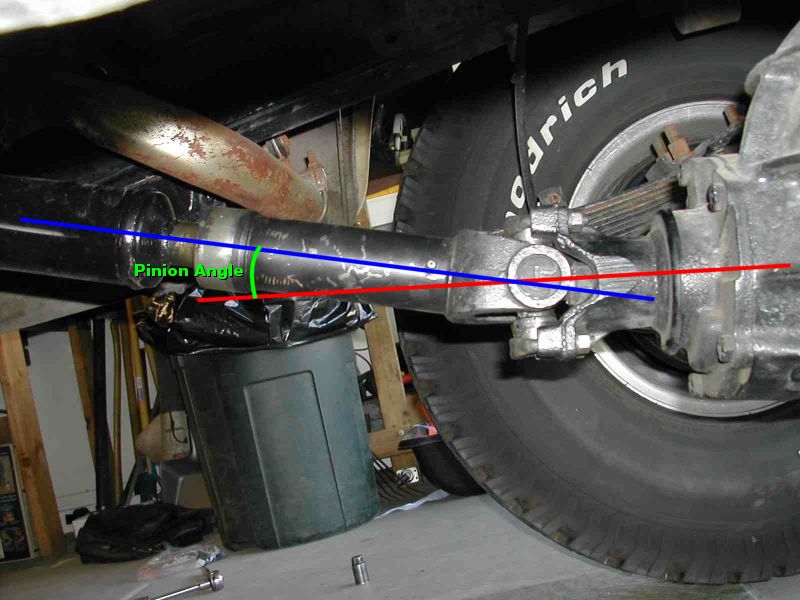

The block should be angled to keep the angle of your axle equal in relation to the output shaft on the transfer case. If you mill down the 2.5 inch block you have (assuming it has been angled correctly to begin with) you will either mill off the angle leaving you with two unangled surfaces or you will be left with a one inch block angled for 2.5 inches either way not perfect but...If you have to go that rout I would go with the flat both sides as a one inch block will have very little adjustment anyway. The result of having an unangled block will be to slightly increased wear on rear drive shaft u-joints. This uncorrected angle shouldn't be enough to cause immediate failure or binding on a one inch lift block. That said get the right ones if you can find them or make them. PS. Thanks again for ordering those snorkles and hubs !!

Re: 70mm x 1,5" lift block

Posted: Sat Aug 14, 2010 7:42 pm

by Jensen

I'm going out of town next week or I'd volunteer my services. If you still need it done in a couple of weeks PM me.

Re: 1,5" lift block

Posted: Sun Aug 15, 2010 11:26 pm

by fexlboi

Thanks Jensen I might come back to you, but at the moment it looks like I found a source for these blocks. Just need to figure out which angle I need. Any idea how to do that?

Re: 1,5" lift block

Posted: Mon Aug 16, 2010 12:22 am

by jessef

Any good angle meter digital or analog.

I would like to think that any good mechanic shop that does driveline work can do/measure this for you.

If not, you can always just buy an angle meter from princess auto or crappy tire and measure the two angles. The difference between the two will be the angle you need on the shim.

Just make sure you don't reverse it. heh. I did that a long time ago and the diff was facing downwards instead of upwards. quite embarrasing.

Re: 1,5" lift block

Posted: Mon Aug 16, 2010 12:35 am

by fexlboi

But how do I measure the angle if the old block is still attached and already on an angle?

Take out the old block. Use 1.5"

rectangled block. Measure. Buy block with right angle?

Update: Found a very informative website:

http://www.4crawler.com/4x4/ForSale/Shims.shtml#FAQ

Re: 1,5" lift block

Posted: Mon Aug 16, 2010 12:57 pm

by Jensen

I usually work out the angles in Autocad, I don't know a simple quick "in the garage" method unfortunately.